Brief Introduction of The Forged Iron/Aluminium Y-Clevis

The Forged Iron/Aluminium Y-Clevis is specifically engineered for power transmission applications. Its production requires advanced manufacturing techniques and strict quality control measures. The quality of the Y-Clevis is indicative of the manufacturer's expertise and dedication to providing top-notch products. It is accompanied by appropriate quality assurance certificates.

In operation, it acts as a critical junction, facilitating the connection of different parts of the power system with high reliability. It exhibits excellent mechanical properties, including strong load-bearing capacity and good resistance to deformation, enabling it to cope with the complex mechanical conditions in power transmission. The selection of iron or aluminium as the material is determined by the specific application context and environmental factors, enhancing the overall performance and longevity of the power system.

Application:

It is commonly used in the interconnection of various components in the power transmission network, such as insulators and support structures. Its primary purpose is to establish a stable and secure connection, ensuring the continuous and efficient transmission of electrical power and the overall reliability of the system.

Standards:

IEC 61466-1:2016

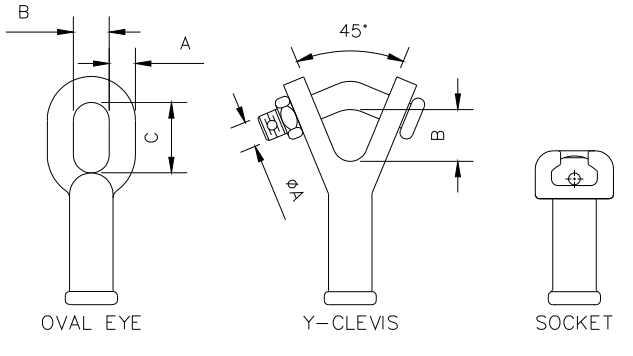

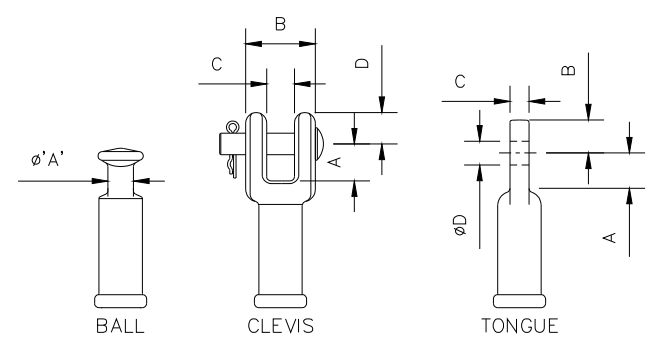

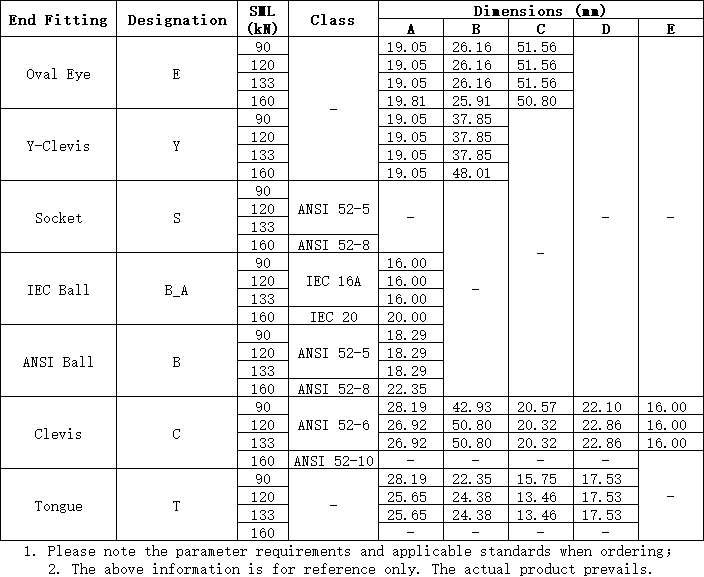

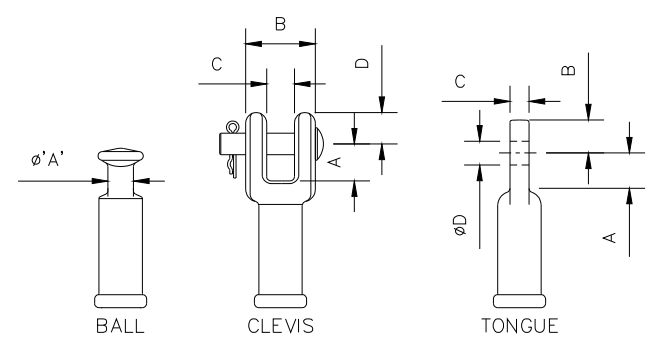

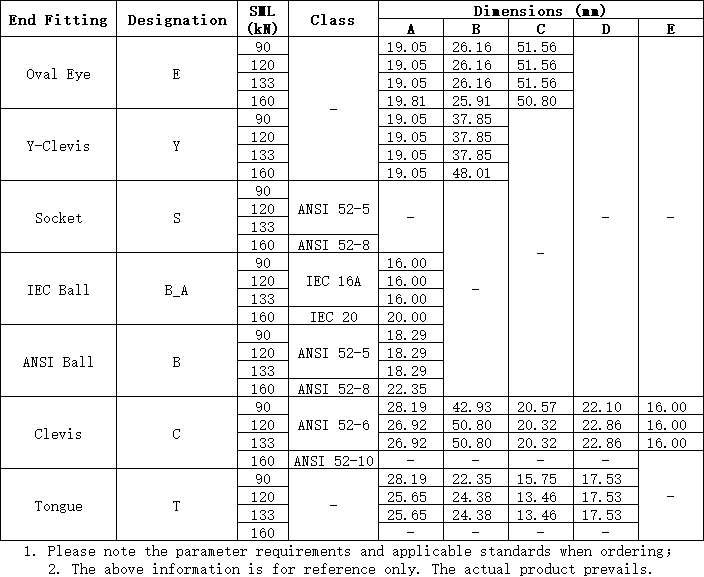

Specifications:

Features:

It can handle the mechanical loads and stresses in power transmission effectively, ensuring the integrity of the connection and minimizing the risk of structural failures. This is crucial for the safe and reliable operation of the power system.

The choice between forged iron and aluminium provides flexibility to meet the diverse needs of different applications. Iron offers superior strength and durability, while aluminium is lighter and has better corrosion resistance in certain environments, making it suitable for specific installation scenarios.

It is designed with precise geometric features and dimensions to ensure a proper fit and alignment with the connected components. This accuracy is essential for maintaining the mechanical and electrical performance of the power system.

It is capable of withstanding a wide range of environmental challenges, such as temperature extremes, moisture, and exposure to pollutants. This durability ensures its long-term functionality and reduces the need for frequent maintenance and replacements.