When it comes to electrical safety, the terms surge protector and surge arrester are often used interchangeably. This confusion is understandable—they both protect electrical systems from voltage spikes. However, their design, application, and performance characteristics differ significantly.

Understanding the difference between these two protective devices is critical whether you're safeguarding your home electronics or engineering a large-scale power grid.

Definition and Function

What is a Surge Protector?

A surge protector, sometimes referred to as a surge suppression device, is a low-voltage component commonly found in homes and offices. Its main function is to protect sensitive electronics such as computers, routers, televisions, and kitchen appliances from transient voltage spikes. These spikes often originate from minor power fluctuations, nearby lightning strikes, or switching events on the grid.

Surge protectors typically incorporate Metal Oxide Varistors (MOVs) or Gas Discharge Tubes (GDTs) that act as a path for the excess voltage to be diverted away from connected devices. MOVs are the most common internal component and are highly responsive, providing milliseconds or even microseconds of reaction time.

What is a Surge Arrester?

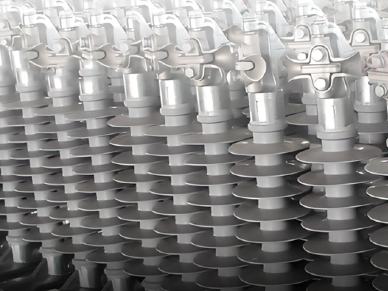

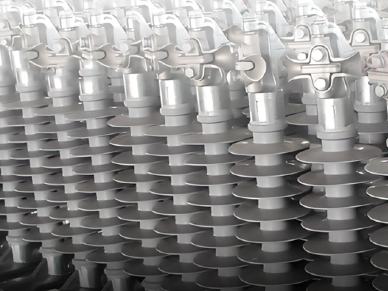

A surge arrester, by contrast, is a high-voltage device designed to protect large-scale electrical systems. These are commonly installed in power transmission and distribution networks, substations, transformers, and renewable energy infrastructure like wind farms and solar plants.

The primary role of a surge arrester is to provide a low-impedance path for overvoltage surges—such as those caused by lightning or switching—to flow safely to ground, thereby preventing damage to insulation and other critical components.

Modern surge arresters typically use zinc oxide (ZnO) as their core material, which offers superior non-linear resistance characteristics. These are referred to as Metal Oxide Arresters (MOAs) and are available in two main types: Zinc Oxide Arresters with Gap and Gapless Zinc Oxide Arresters.

Key Differences

1. Voltage Range and Application Level

One of the most significant differences between a surge protector and a surge arrester lies in the voltage range and application level they are designed to handle.

Surge Protectors are built for low-voltage systems, typically operating under 600V. They are designed to shield consumer electronics and IT equipment, such as laptops, routers, televisions, and desktop computers, from short-duration voltage spikes. These spikes may result from local power grid fluctuations, electrical switching, or nearby lightning strikes.

In contrast, a Surge Arrester is engineered for medium to high-voltage environments, often rated from 3kV to over 800kV, depending on the application. Surge arresters such as the 34kV Surge Arrester and the 132kV Surge Arrester are critical in protecting power infrastructure. These include substations, overhead transmission lines, underground cable systems, wind and solar power plants, and large industrial installations. Surge arresters are essential in preventing insulation failure, equipment damage, and long-term reliability issues in electrical grids.

2. Internal Components

The internal design of a surge protector and a surge arrester reflects their intended use and voltage level.

Surge Protectors typically use Metal Oxide Varistors (MOVs), Gas Discharge Tubes (GDTs), or similar semiconductor-based components. Many consumer-grade surge protectors also integrate EMI/RFI filtering circuits, which help suppress electrical noise that can interfere with sensitive electronics. While these components are quick-acting and effective for lower energy surges, they are not capable of handling the large transient overvoltages seen in utility systems.

A Surge Arrester, on the other hand, relies heavily on Zinc Oxide (ZnO) varistors for surge protection. Earlier designs used ZnO blocks with spark gaps, where the gap allowed an arc to form, discharging the surge. However, this introduced maintenance challenges due to residual arcing. Modern Metal Oxide Arresters (MOA) are generally gapless, which eliminates arcing risk and enables instantaneous response to overvoltage events. Gapless Zinc Oxide Arresters provide superior durability, extended service life, and higher reliability, especially under harsh environmental conditions.

3. Installation Location and Use Cases

The installation method and usage scenarios for surge protectors and surge arresters are markedly different due to their respective voltage handling capabilities.

Surge Protectors are designed for ease of use. They are often installed directly into wall outlets, power strips, or rack-mounted power distribution units (PDUs). These devices are perfect for home offices, media rooms, commercial offices, and server environments where plug-and-play convenience is necessary and space is limited.

Surge Arresters, however, are permanently installed in electrical infrastructure. Typical locations include high-voltage substations, distribution feeders, switchyards, and renewable energy installations such as wind turbines and solar farms. A surge arrester is essential in any grid-based system that is vulnerable to transient overvoltages due to lightning strikes, switching operations, or system faults. Their strategic placement helps maintain grid stability and equipment longevity, particularly in regions prone to severe weather or fluctuating load conditions.

Comparative Applications

Surge Protector: Where and Why?

Residential homes: Protect smart TVs, gaming consoles, computers, and smart appliances.

Office environments: Secure printers, modems, routers, and workstations.

Data centers: Prevent downtime and equipment failure due to minor voltage surges.

These devices are relatively inexpensive and easy to replace. However, they are not suitable for handling the extreme voltages found in industrial or utility-grade environments.

Surge Arrester: Critical Use Cases

Substations and Transmission Networks: 132kV surge arresters are commonly used in high-voltage transmission to prevent equipment failure and insulation breakdown.

Distribution Systems: 34kV surge arresters protect medium-voltage feeders and switchgear.

Renewable Energy Installations: Wind farms, solar stations, and battery storage systems all use surge arresters to ensure system integrity during voltage disturbances.

In all these applications, MOA surge arresters are preferred for their rapid response time and long service life.

Performance and Protection Capacity

Response Time

Surge Protectors respond in nanoseconds to microseconds—suitable for electronics that require fast but low-energy protection.

Surge Arresters, particularly gapless ZnO types, respond within microseconds, preventing arc-over or flashover in high-voltage environments.

Energy-Handling Capability

Surge Protectors: Designed for surges up to a few hundred joules.

Surge Arresters: Can safely handle tens of thousands of amperes, and are rated to dissipate kilojoules to megajoules of energy without permanent damage.

Reusability and Durability

Surge Protectors: Degrade over time, especially after repeated surges; may need regular replacement.

Surge Arresters: MOA designs offer self-healing properties and can endure multiple high-energy surges, often lasting 10-20 years in service with minimal maintenance.

Which One Do You Need?

For Homeowners and Small Businesses:

Choose a surge protector if you want to shield your personal electronics from minor voltage fluctuations. Look for units with an energy rating that suits your equipment and with visual indicators showing protection status.

For Utilities, Engineers, and Industrial Operators:

Opt for a surge arrester—especially a gapless zinc oxide arrester—when protecting high-voltage assets. Depending on your network configuration and voltage level, you might need:

Conclusion

While surge protectors and surge arresters share a common goal—protecting systems from voltage spikes—they are designed for entirely different environments. Surge protectors are ideal for home and office use, while surge arresters are indispensable in industrial and utility-scale power systems.

The advancement of Metal Oxide Arrester (MOA) technology, particularly in gapless zinc oxide arresters, has transformed high-voltage protection with better response times, lower maintenance needs, and extended service life. Whether you’re working with a 34kV distribution system or a 132kV transmission network, selecting the right arrester type can mean the difference between system stability and costly downtime.

For more information about surge arrester products and tailored protection solutions, we recommend exploring the expertise of Hebei Jiuding Electric Co., Ltd. Their industry-leading technology, professional support, and proven reliability make them a trusted partner for modern power protection.