Introduction

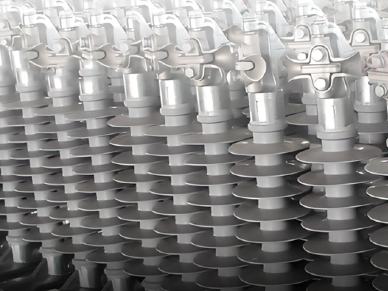

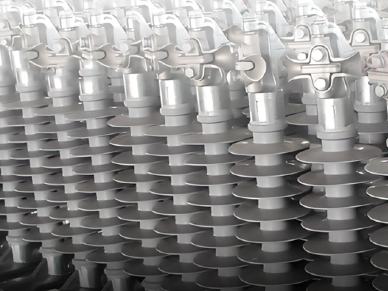

Insulators are vital for safe and efficient power transmission. Among the different types, composite insulators with FRP Core rod are increasingly recognized for their extended service life. The durability of these insulators plays a crucial role in reducing maintenance costs and enhancing system reliability. In this article, we will explore why FRP Core rod offers a longer lifespan compared to traditional materials, ensuring continuous power flow and greater long-term value.

Material Composition of FRP Core Rods

Key Components of FRP Core Rods

FRP core rods are primarily composed of fiberglass and resin, which form a durable and strong composite material. Fiberglass provides excellent tensile strength, while the resin binds the fibers together, contributing to the overall stability and robustness of the rod. This combination results in a core that is lightweight yet capable of handling significant mechanical stress, making it an ideal choice for high-voltage applications where durability is paramount.

Hydrophobic Properties and Their Impact

This table highlights the hydrophobic properties of FRP core rods, their role in preventing water accumulation and flashover, and how they compare to traditional materials. The details provide technical insights into why these properties contribute to the longer lifespan of FRP insulators.

| Factor | FRP Core Rods | Porcelain Insulators |

| Hydrophobic Nature | FRP core rods have a hydrophobic surface that repels water, reducing the likelihood of flashover. | Porcelain insulators are more prone to water retention, which can cause flashover in wet conditions. |

| Water Resistance Mechanism | Water droplets bead up on the surface, preventing the formation of water films that conduct electricity. | Porcelain absorbs water, which can form continuous water films, increasing the risk of electrical failure. |

| Flashover Prevention | The hydrophobic surface ensures minimal risk of flashover in polluted or wet environments. | Flashover is more likely in polluted or wet environments due to the absorption of water on the porcelain surface. |

| Performance in Polluted Areas | FRP core rods maintain their insulating properties even in environments with high pollution or humidity. | Porcelain insulators degrade faster in polluted areas due to water retention, which leads to reduced insulation efficiency. |

| Maintenance Requirements | Minimal cleaning is needed since the surface repels water and contaminants. | Requires frequent cleaning to prevent build-up of water and pollutants that lead to flashover. |

Tip:FRP core rods' hydrophobic properties make them ideal for use in regions with high humidity or pollution, significantly reducing the need for regular maintenance.

Temperature Resistance of FRP Core Rods

FRP core rods are highly resistant to temperature fluctuations, maintaining their structural integrity even under extreme conditions. They can operate effectively in a wide range of temperatures, from -55°C to 300°C, without undergoing degradation. This makes them ideal for use in environments where temperature extremes are a regular occurrence, ensuring that the insulator remains functional over a longer period.

Environmental Resistance Contributing to Longevity

Resistance to UV Radiation

One of the challenges that insulators face is exposure to ultraviolet (UV) radiation, which can degrade materials over time. FRP core rods are specifically designed to resist UV radiation, preventing surface cracking and degradation that would typically occur in traditional materials. This resistance allows FRP core rods to retain their insulating properties even when exposed to prolonged sunlight, significantly extending their service life.

Pollution and Chemical Resistance

Another factor that contributes to the long lifespan of FRP core rods is their resistance to pollution and chemical agents. In environments with high levels of industrial emissions, salt from coastal areas, or other pollutants, traditional materials like porcelain often experience surface degradation. FRP core rods, however, are resistant to these corrosive elements, maintaining their integrity and performance even in harsh environments.

Corrosion Resistance

Corrosion is a major issue for many traditional insulators, especially those exposed to moisture and chemical gases. FRP core rods, however, are highly resistant to corrosion, preventing the breakdown of the material and ensuring long-term durability. This resistance to corrosion is crucial in ensuring the insulator continues to function reliably over time, particularly in coastal or industrial regions.

Design Advantages of FRP Core Rods

Lightweight and Flexible

FRP core rods are significantly lighter than traditional porcelain or glass insulators. This lightweight design reduces mechanical stress during installation and operation, making the rods easier to transport and install. Additionally, the flexibility of FRP core rods allows them to better withstand environmental stress, such as wind and vibration, without the risk of cracking or failure.

High Mechanical Strength

Despite their lightweight nature, FRP core rods offer exceptional mechanical strength. The fiberglass reinforcement ensures that the core rods can handle significant tensile forces, making them ideal for high-stress applications such as power transmission lines. This strength is vital for maintaining the integrity of the insulator under challenging conditions, such as wind, ice, and vibration.

Impact on Installation and Maintenance

The lightweight and high-strength design of FRP core rods not only reduces installation time but also contributes to lower maintenance needs. These insulators are less prone to cracking, chipping, or breaking during installation or operation, minimizing the frequency and cost of repairs. This ease of installation and maintenance adds to the overall value of FRP core rods in electrical systems.

Performance Under Extreme Conditions

Operating in Harsh Climates

FRP core rods are engineered to endure extreme environmental conditions, from freezing temperatures to scorching heat. Their fiberglass composition ensures that they remain resilient in both low and high-temperature extremes, without compromising their insulating properties. These rods also exhibit excellent moisture resistance, preventing the absorption of water, which can lead to electrical failures in traditional materials. As a result, they are the preferred choice for power transmission systems in regions experiencing harsh, fluctuating climates.

Resistance to Overvoltage

FRP core rods provide superior protection against overvoltage conditions, such as lightning strikes, power surges, and transient electrical spikes. Their robust structural integrity allows them to absorb and dissipate these voltage surges without compromising their insulation performance. Unlike conventional porcelain insulators, which may crack or degrade under such stress, FRP core rods continue to perform effectively, reducing the likelihood of power system failure. This makes them ideal for regions with frequent electrical disturbances, ensuring a more reliable and durable system.

Long-Term Durability in Diverse Environments

The exceptional durability of FRP core rods is a result of their resistance to a wide range of environmental factors. They can endure exposure to pollutants, extreme weather conditions, and mechanical stress without losing their integrity. The resin in FRP rods resists chemical corrosion, while the fiberglass core provides excellent mechanical strength, ensuring that the rods can withstand high winds, ice loads, and seismic activity. This ability to maintain peak performance across various conditions gives FRP core rods a much longer operational life compared to traditional materials like porcelain or glass.

Comparison with Traditional Insulators

Porcelain vs. FRP Core Rods

When comparing porcelain insulators and FRP core rods, there are several factors to consider, including application, technical specifications, durability, and maintenance requirements. The following table summarizes the key differences and advantages of both options:

| Comparison Factor | Porcelain Insulators | FRP Core Rods |

| Applications | Used in traditional power transmission systems, ideal for stable environments | Suitable for harsh environments with extreme temperatures, humidity, and pollution |

| Technical Specifications | High voltage tolerance, but prone to breakage in harsh conditions | High mechanical strength, resistant to extreme temperatures, humidity, chemical corrosion, and UV radiation |

| Lifespan | Can last up to 60 years in ideal conditions, but degrades faster in harsh environments | Achieves 20-30 years of lifespan, even in more demanding environments |

| Seismic Resistance | Fragile, prone to cracking under mechanical stress | Strong seismic resistance, can withstand greater mechanical stress and vibration |

| Temperature Resistance | Prone to cracking with temperature fluctuations | Wide operating temperature range (-55°C to 300°C) |

| Maintenance Requirements | Requires regular cleaning and inspection to prevent contamination and flashover | Less maintenance needed, self-cleaning properties reduce maintenance costs |

| Environmental Adaptability | Poor resistance to UV radiation, pollution, and chemical corrosion | High resistance to UV radiation, pollution, and chemical corrosion, ideal for harsh environments |

Tip:Switching to FRP core rods can enhance system reliability, reduce long-term maintenance costs, and perform better in harsh environmental conditions.

The Benefits of FRP Over Other Materials

FRP core rods offer numerous advantages over other materials used in insulators. Their lightweight design, resistance to UV radiation, chemical corrosion, and temperature extremes make them a superior choice for modern electrical systems. These benefits translate into longer service life, reduced maintenance costs, and improved overall system reliability.

Case Studies and Real-World Applications

In real-world applications, FRP core rods have proven to be a reliable and durable choice. Case studies from regions with extreme climates, high pollution, and frequent electrical surges demonstrate the longevity and performance of FRP core rods. These examples highlight the practical benefits of using FRP in power transmission systems, especially in challenging environments.

Maintenance and Inspection Needs for Longer Life

Self-Sustaining Features of FRP Core Rods

FRP core rods’ self-sustaining nature is a key advantage, reducing the frequency of maintenance and cleaning. Their hydrophobic surface prevents water and pollutants from adhering to the rod, minimizing the risk of flashovers and contamination buildup. This feature not only improves their operational efficiency but also reduces maintenance costs and downtime. Over time, this self-sufficiency results in a more cost-effective, reliable solution for long-term electrical system performance.

Monitoring and Preventive Measures

To ensure the continued longevity of FRP core rods, periodic inspections and monitoring are essential. Regular checks for surface degradation, hydrophobicity, and mechanical strength can help identify potential issues before they lead to failure. Preventive maintenance, such as cleaning the surface or replacing damaged components, can further extend the lifespan of these insulators.

Replacement Strategies

Although FRP core rods are designed to last, timely replacement is crucial to avoid unexpected failures. Using condition-based monitoring techniques like partial discharge detection and insulation resistance testing can help assess the health of the rods. By replacing aged insulators before they fail, utilities can avoid costly downtime and ensure the system remains reliable. Proactive replacement strategies enhance overall system reliability and minimize the risk of unplanned outages.

Conclusion

FRP core rods offer significant advantages over traditional insulators, particularly in terms of longevity, performance, and maintenance. Their unique material composition, environmental resistance, and design features allow them to endure harsh conditions and maintain performance over extended periods. This makes them an excellent choice for modern power transmission systems that demand long-term reliability. Hebei Jiuding Electric Co., Ltd. provides high-quality FRP core rods, offering superior durability, reduced maintenance costs, and enhanced system reliability, ensuring long-lasting power transmission solutions for various industries.

FAQ

Q: Why do FRP Core Rods have a longer life compared to traditional insulators?

A: FRP Core Rods are more durable because of their resistance to environmental factors like UV radiation, temperature fluctuations, and chemical corrosion. These properties help extend their lifespan compared to traditional porcelain or glass insulators.

Q: How does the material composition of FRP Core Rods contribute to their longevity?

A: The fiberglass and resin in FRP Core Rods provide high tensile strength and resistance to mechanical stress, allowing them to endure harsh conditions. This makes them more reliable and longer-lasting than traditional insulator materials.

Q: Can FRP Core Rods perform in extreme climates?

A: Yes, FRP Core Rods are designed to withstand extreme temperatures and high humidity without degradation, ensuring their effectiveness in harsh climates like freezing cold or intense heat.

Q: What are the environmental benefits of using FRP Core Rods in electrical systems?

A: FRP Core Rods offer superior resistance to UV radiation, pollution, and chemical exposure, making them ideal for areas with high environmental stress. They help reduce the frequency of maintenance and replacements.

Q: How does the hydrophobic property of FRP Core Rods impact their lifespan?

A: The hydrophobic nature of FRP Core Rods prevents water accumulation, reducing the risk of flashovers and electrical failures. This property contributes to their longer lifespan, especially in wet or polluted environments.